Cooperative Robot Workstation

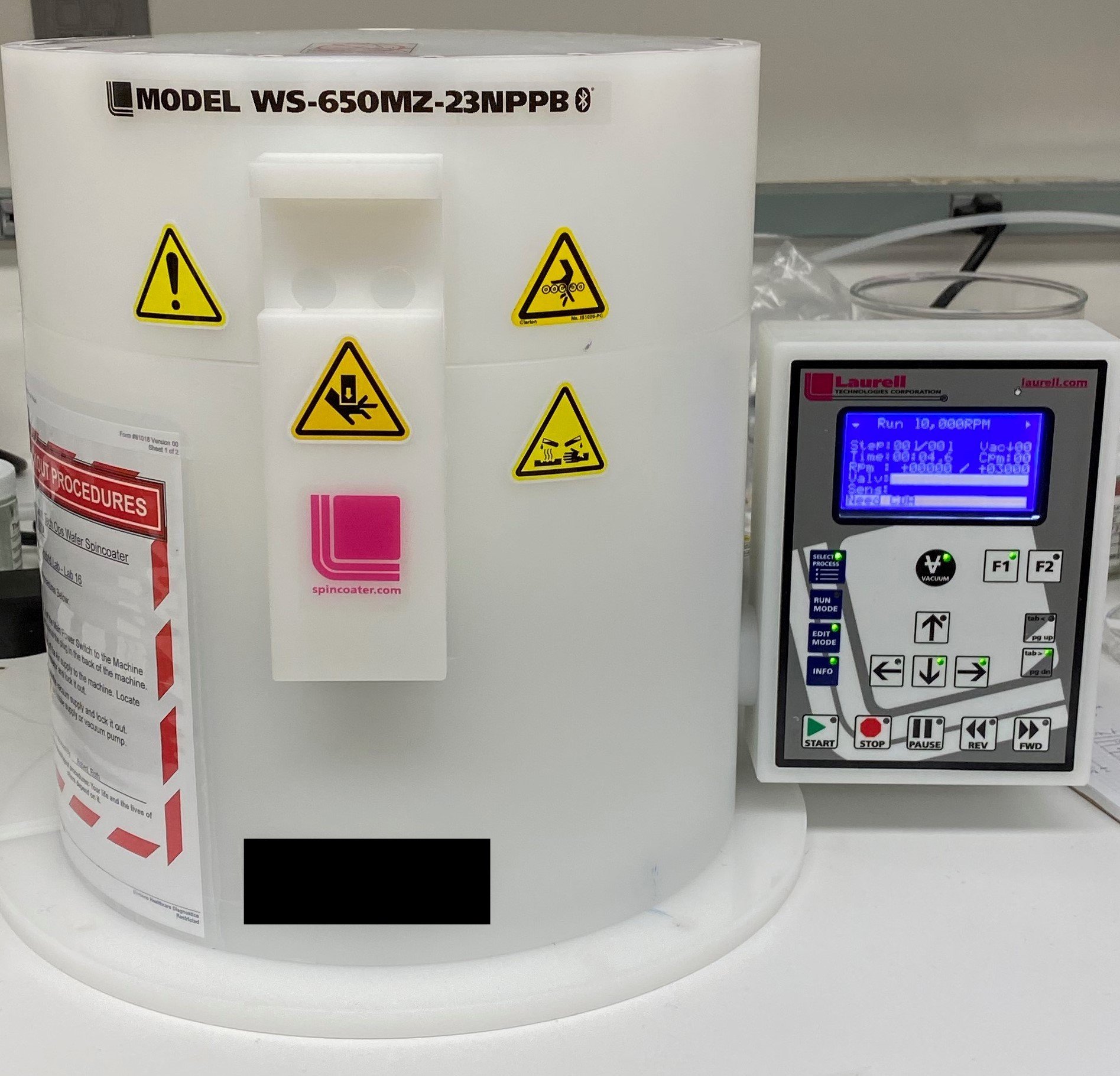

I worked on a project at Siemens Healthineers to create a cooperative robot workstation that would partially automate a repetitive task involving the use of a pipette and spinner to evenly coat silicon wafers with a substance. The task was only performed a few dozen times daily, but the waiting time for the spinner to complete its cycle between each wafer made it suitable for automation by a robot.

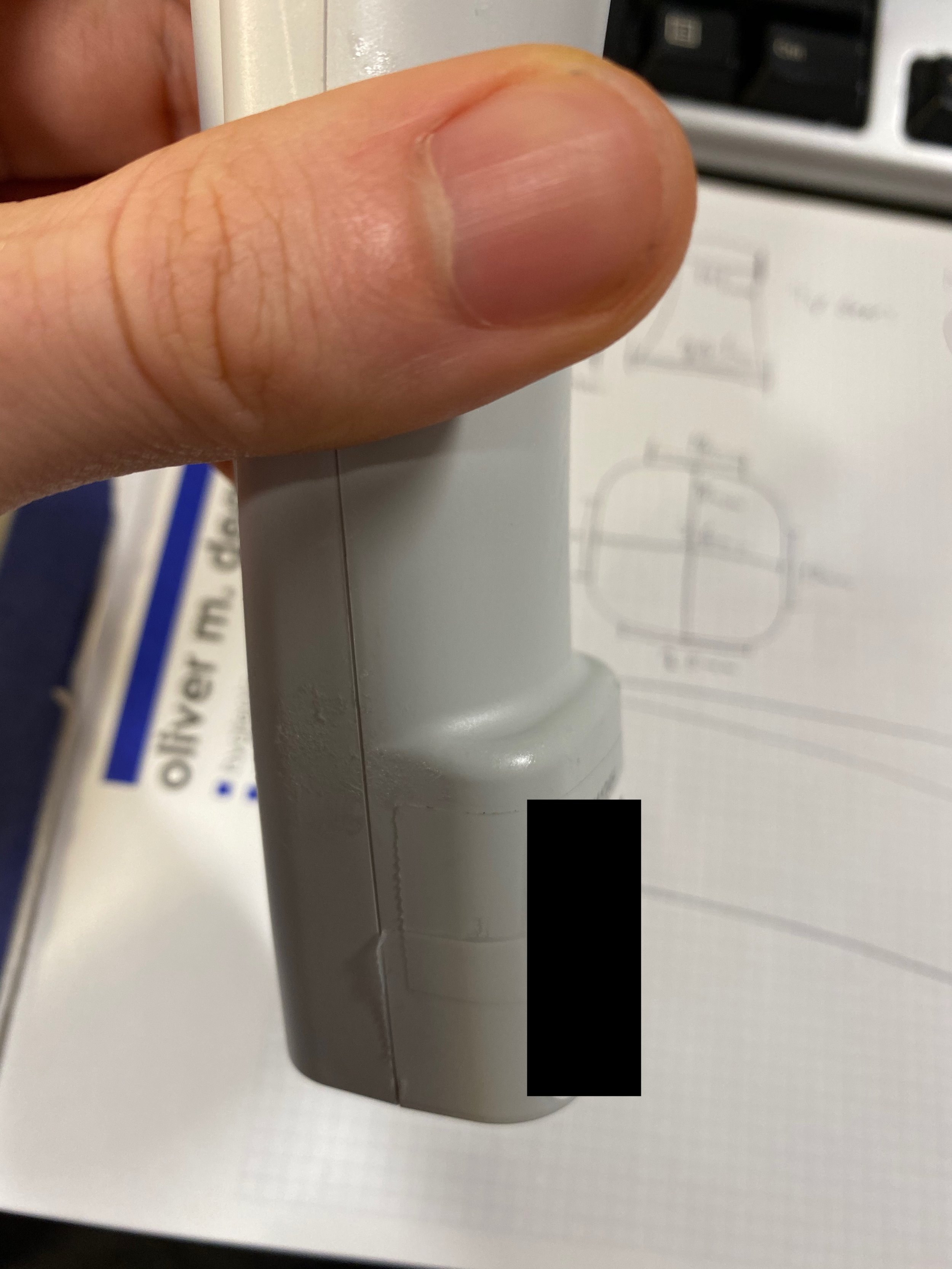

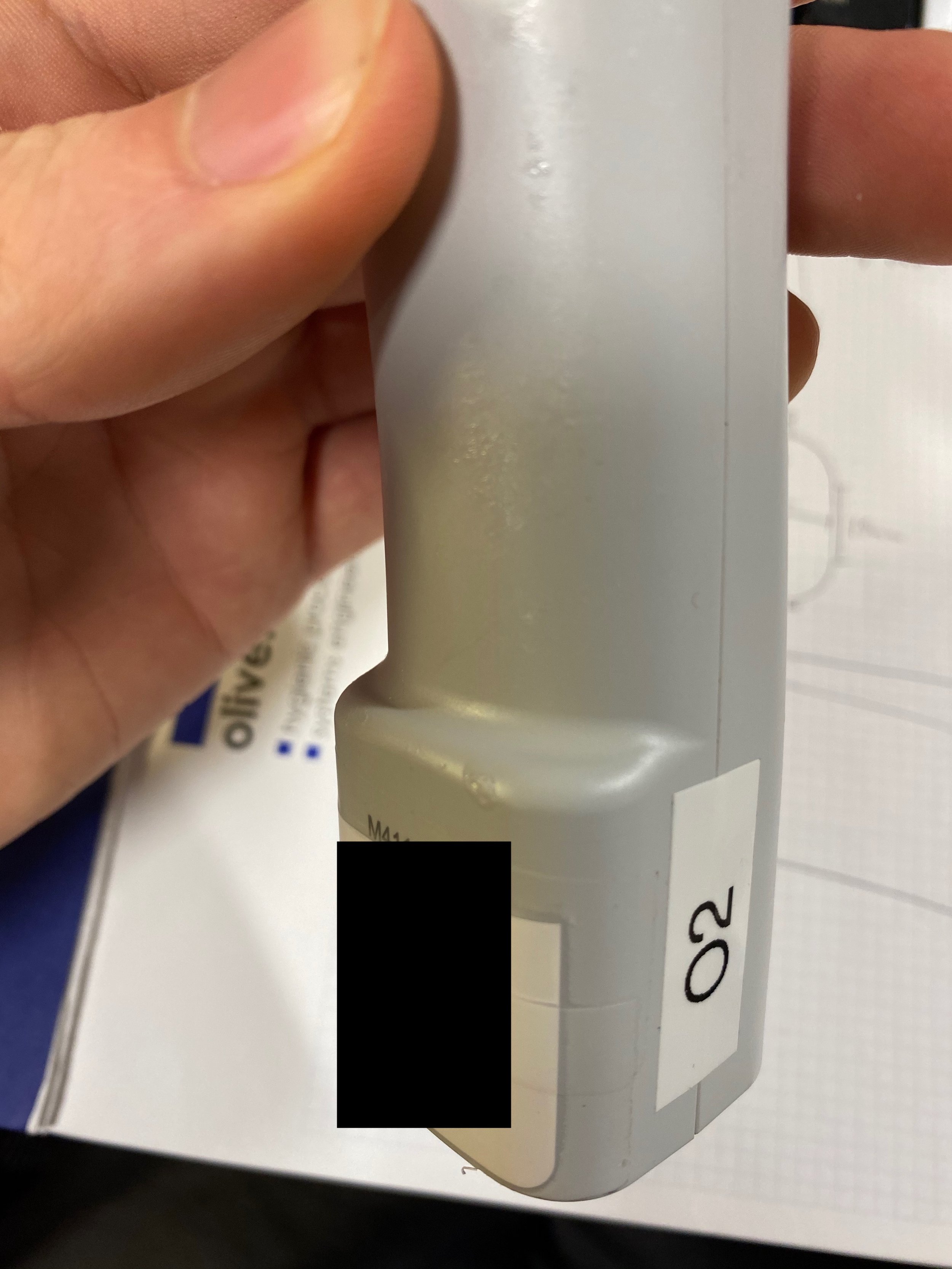

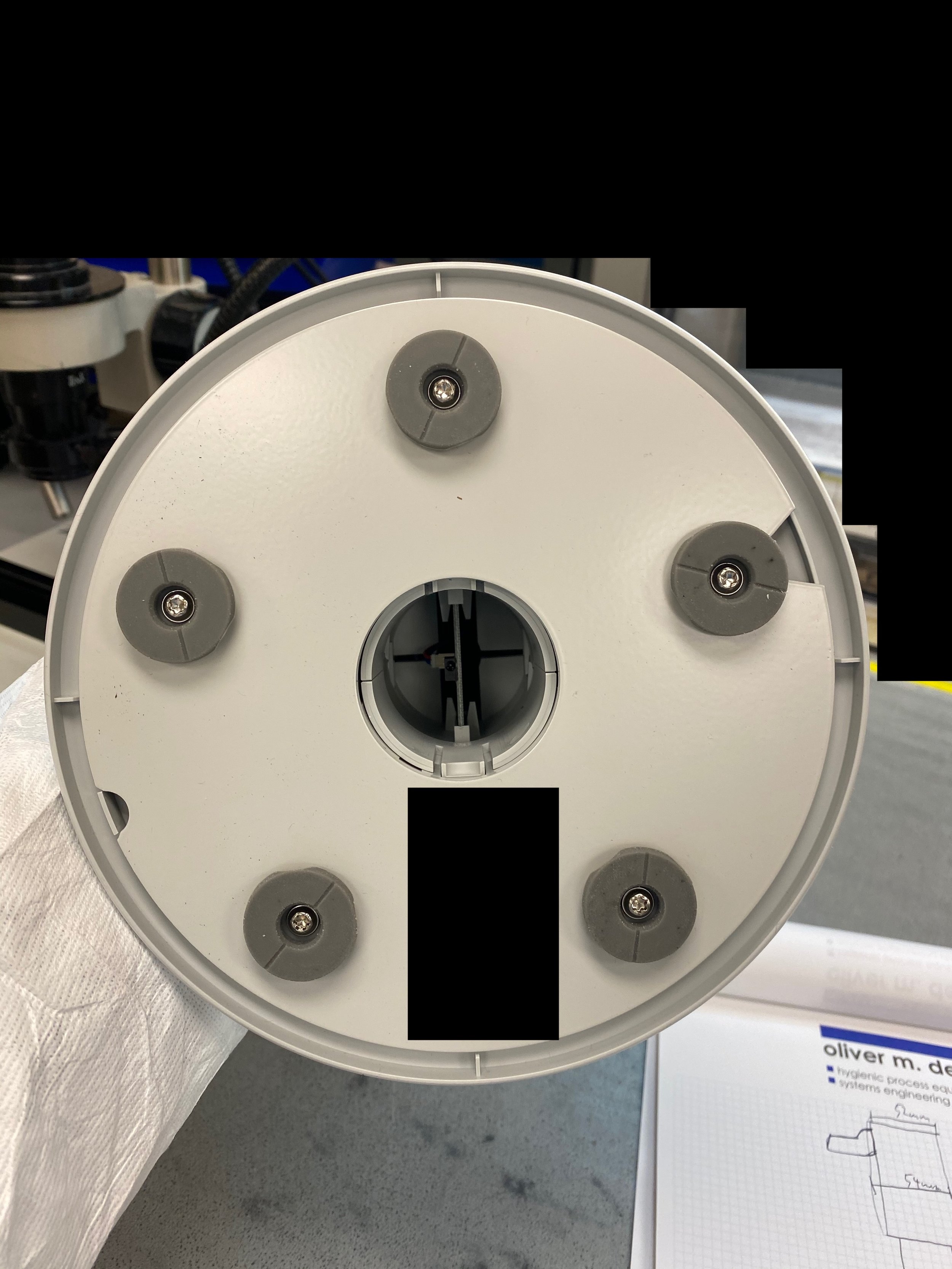

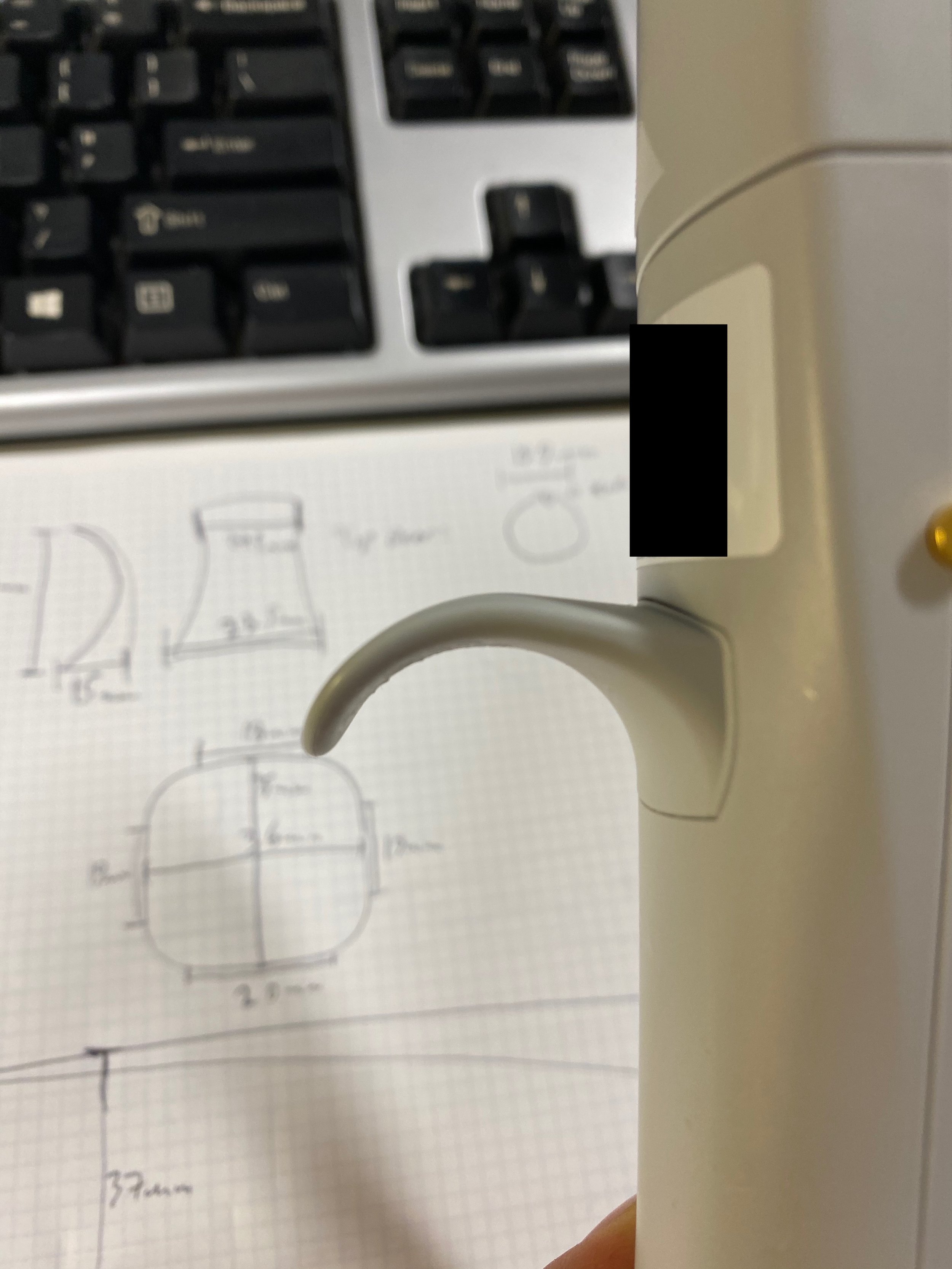

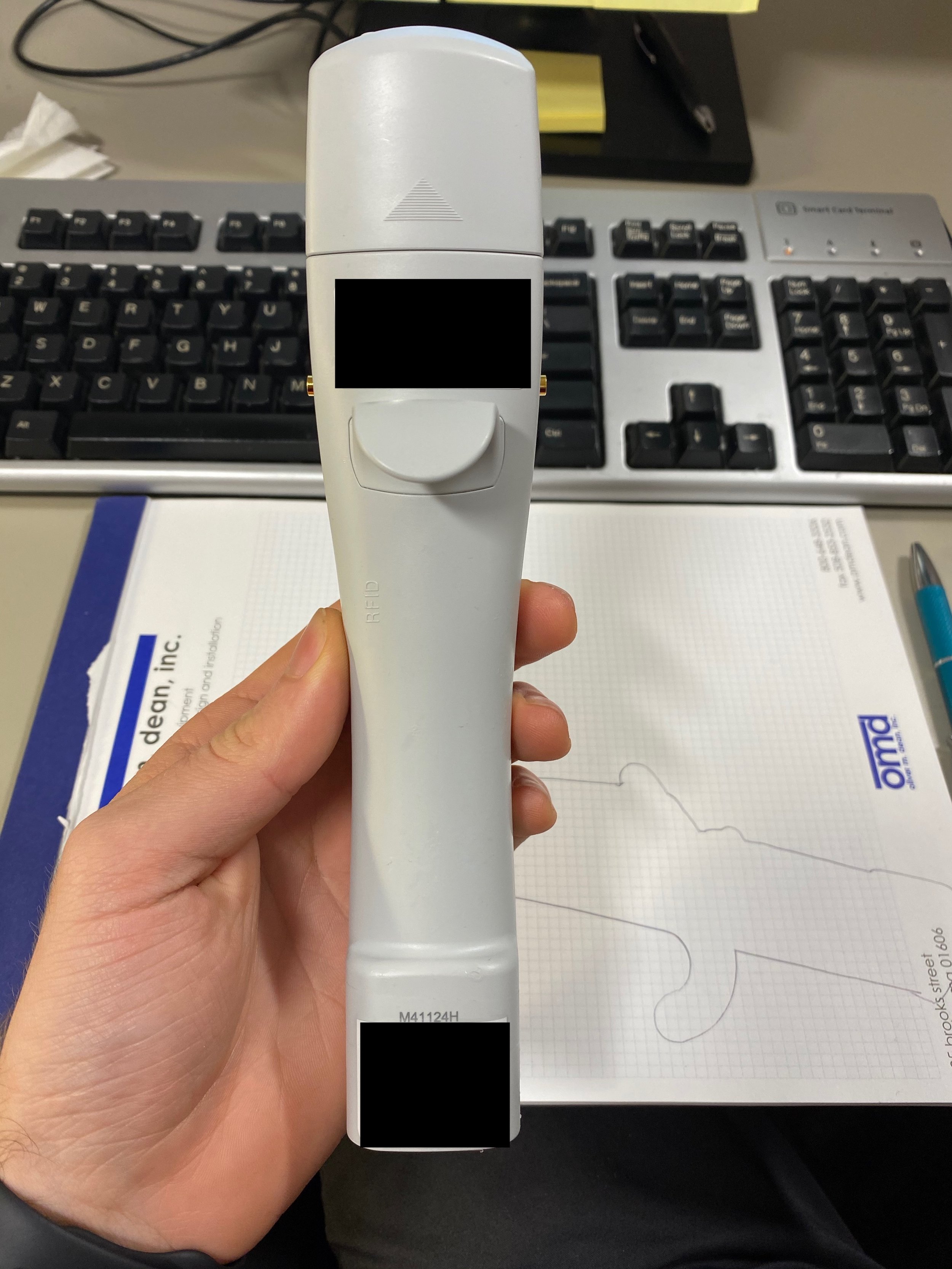

I began by researching the relevant procedures used by technicians and speaking to them to ensure their needs were met and the proper procedure was followed. Next, I recreated in CAD all the components that the robot would interact with, including the pipette, pipette charging stand, the spinner, and a custom gripper part for the UR3e robot.

I also designed a storage rack for the robot to place trays of completed wafers in, as well as components to mount the pipettes and spinner to the table. A drying rack was also needed to prevent the substance from dripping off the completed wafers before they were placed on the trays.

I created several possible layouts of the workstation with all the components and had a design review with my coworker and manager. The final layout was selected and I added further detail to the CAD design and created a video showcasing the robot's function using SolidWorks motion studies.

Workstation Motion Study

This video shows the end result of the project and my final design for the workstation. The motions of the robot were meant to show its range of motion while it was performing the task to better have an understanding of how it would interact with the technicians which placed the trays of wafers on the workstation.